16

Jul

Torch Brazing

Depending on the temperature needed for your assembly, the fuel gas (i.e., acetylene, propane, or natural gas) can be burned with air, compressed air, or oxygen. Torches that are specifically designed with multiple tips or flames can be used by constantly moving the flame to disperse the heat evenly among the assembly to avoid localized overheating, and compromise the strength of the joint. Here are the different techniques with equipment, depending on the assembly that needs to be welded.

- For brazing small components and thin sections, you would want to use torches that provide the lowest heat and flame temperature. These torches used for these applications are the air-natural gas and air-acetylene.

- Torches that provide excellent results on many brazing applications are oxygen with natural gas, or other gases such as propane or butane. Although these produce a higher flame temperature, the brazing should be applied using a slightly reduced or neutral flame for better results.

- Aluminum and nonferrous alloys (metals that does not contain iron in appreciable amounts), should be brazed using the oxyhydrogen torch because it operates at a lower temperature.

- Torch heating for brazing to fill in joints of your assembly, require the use of flux- covered or –cored filler metal rods. Natural gas is used for this technique because of its low flame temperature which reduces the risk of overheating the joint as well as the metal filler. Only copper-phosphorus fillers are self-fluxing as they used in brazing in air without flux. However, all other filler metals require fluxes. The filler metal can either be preplaced or face-fed into the joint, as the joint is prepared for brazing. Keep in mind that torch brazing techniques used with oxyfuel gas welding equipment differ from those used for oxyfuel gas welding.

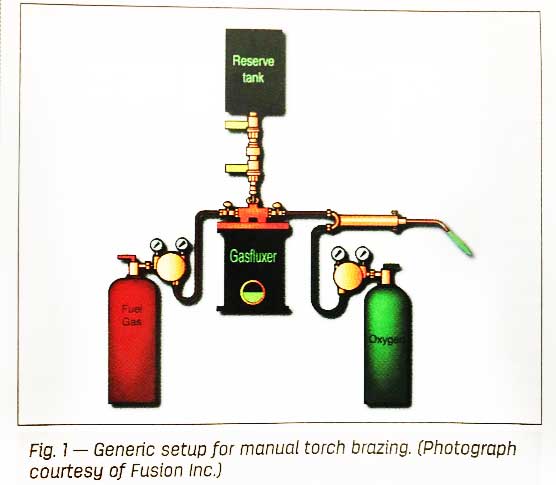

- Manual torch brazing is a simple technique, without automation. This technique is typically used for assemblies that have different sections, not equal in size. Only the braze joint is visible and receives the direct heat. The torch used has a single tip that is often used for single or multiple flames. If you have a large volume of assemblies that need to be produced, a mechanical option can be setup to either move the pieces of the assembly or the torches, or both during brazing.